Gelling Agents | Organophilic Clay

Gelling Agents Organic bentonite, also known as rheological modifier, is an indispensable chemical additive in oilfield drilling. Organophilic clay bentonite is an important suspending agent in completion fluid, workover fluid and fracturing fluid.

Whether you are an oilfield service company or an end user, we welcome you to inquire about our products organoclay. Our company provides you with the high quality organic clay bentonite and the competitive price.

Gelling Agents Organoclay

Product Name : Gelling Agents

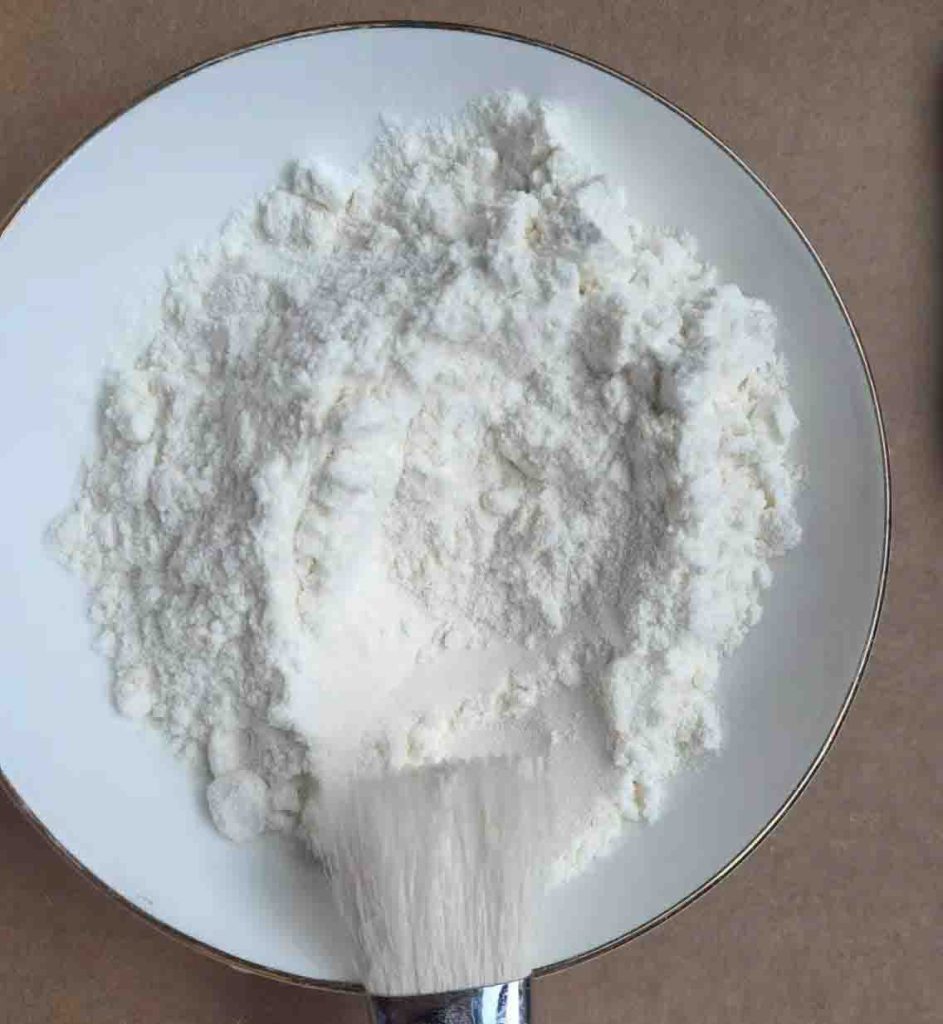

Color : Off – White Organoclay Powder

Application: Thixotropic Uses Paints | Coatings | Grease | Oil drilling Mud

Materials : Alkyl Quaternary Ammonium bentonite

Certificate: ISO 9001

Packing: 25Kg/Bag,22.68 (50lb)/Bag Or Customize

16MT/20FCL With Pallet, 22MT/40FCL With Pallet.

Features : Thixotropy, Thickening, Anti-Settling, Anti-Sagging,

Sample Service : Oilfield chemicals Organophilic clay Sample Available.

Brand : Camp – Shinning Organoclay

Gelling Agents | Organophilic Clay

Gelling Agents organoclay in oil based mud can play the role of thickening, stabilizing and suspending.

In oil and natural gas operations, organic bentonite will help oil–ased mud to protect the well wall, lubricate the bit, and carry some salt out of the country. Both oil–ased mud, well completion and workover fluids need rheology modifiers.

Sale Dept: [email protected]

Cell(Whatsapp): +86-13185071071

Gelling Agents Properties

Composition Organic derivative of a montmorillonite clay

Appearance Fine powder, white

Moisture content (105℃,2hr) ≤3.5%

Loss on ignition (1000℃) 40%-44%

Bulk density 0.40~0.60g/cm3

Fineness (<74μm, %) ≥99.8%

Dispersion fineness (μm) ≤10

Advantages

- High purity, low silica content.

- Easy dispersing, fine particle size.Easy to use, no need to pregel

- High viscosity and high thixotropic.

- Wide application range. It can be applied in almost all resins and solvents

- Gel is very transparent and of light color.

Application

Oilfield chemicals Organophilic clay are used in the following applications:

- Paints including top grades paint, decorative paint, industrial paint, traffic paint etc.

- Inks

- Sealant

- Cosmetic

- Cleaning agent

- Oil Drilling Mud

- Fracture Fluids

Safety

All safety information is provided in the Material Safety Data Sheets for Zhejiang Camp-Shinning New Material Co., Ltd.

Package

Kraft paper bag with PE liner or multi-wall paper sacks or customized. 25kg/bag or 22.68kg/bag or customized

Storage

Thixotropic gel has a shelf life of 2 years, and should be stored in ventilated cool and dry place.

Notice

The information on use is based on data which are believed reliable, but any recommendation or suggestion made is without guarantee or warranty, since the conditions of use are outside our control. All products are sold on the conditions that purchasers shall make their own tests to determine the suitability of such products for their purpose and that all risks are assumed by user. We disclaim any responsibility for damages resulting from careless or improper handling or use. Nothing herein is to be taken as permission, inducement or recommendation to practice any patented invention without a license.

Hectorite Clay Suppliers

How To Use Gelling Agents

- Pre-gel method

- Polar activator is not necessary:

- Main solvent xylene: 95~92%

- Thixotropic clay :5~8%

- Dispersing 5-15min, gel is finished.

- Polar activator is necessary:

- In aromatic solvent, the recommend activator is methyl acohol/water (95%/5%)/ acolhol/water (95%/5%), the dosage is 33%-45% based on the weight of CP-720B.

- In mineral oil (such as 200#), white oil, diesel oil, the recommend activator is methyl acohol/water (95%/5%)/acolhol/water(95%/5%), the dosage is 33%-60% based on the weight of CP-720B.

- Procedure of adding gel:

- Charge solvent and resin to mill

- Slowly add the gel

- Dispersing 5-10min

- Wetting agent (if required)

- Disperse completely to desired fineness

- Dilute to desired viscosity

- Add directly with powder

- Charge solvent and resin

- Add Thixotropic clay slowly

- Disperse 10-15min

D .Add polar activator (if necessary)

- Disperse 10-15min at high speed

- Add wetting agent and other additive

- G.Grind and next procedure

It can be added directly in powder under high shear condition. The addition is recommended to be before grinding procedure to get the best effectiveness. Addition level is commonly 0.1%~2.0%. If add polar activator and make pre-gel, better efficiency can be achieved.

Bentonite clay for foundry