Your Best Rheological Modifier Supplier & Manufacturer In China

Camp Shinning is one of the leading OEM rheological modifier manufacturers in China. Our full capability on water based rheological modifier and solvent based rheology modifier could improve good thixotropy, dispersibility, rheology and suspension, as well as competitive organoclay price.

We can manufacture rheological modifier for oil field , rheology modifier for grease, rheological modifier for paints coatings, rheological modifier for inks,and more.

Send us your requestment now!

Why Choose Camp Shinning's Rheological Modifier

- ISO Certified Company

- Strong R&D Team Of Rheological Modifier

- 20 Years Of Rheological Modifier Experience

- Camp Shinning Has Own Bentonite Mine With Competitive Organoclay Prices

- Wide Applications, Including Paints, Coatings, Inks, Greases, Fracturing, Organoclay For Oilfield Drilling

- Rich Experience In Cooperation With World-Class Well-Known Companies

- Rheological Modifier With Free Samples To Support Your Market Development

- Reply Within 24 Hours

The Best Selling Rheological Modifier

Why should you OEM rheological modifier from Camp Shinning ? Simply because rheological modifier is the strongest additive for the

paints,coatings,inks,grease and oil drilling mud. And, Camp Shinning is the rheological modifier manufacturer who could offer you one-stop solution.

We have full capacity on thixotropy, dispersibility, rheology and suspension. At the same time, Camp Shinning can also fully support you in the oil drilling

field.Because in drilling mud,Camp Shinning has fully experience to improve your suspension abbility in rheological modifier

Rheological Modifier Use For Oil Drilling Mud

Rheological modifier is a drilling chemical with unique rheological structure that suspends weighting materials and other solids with less increase in viscosity and gel strength than conventional bentonite.Rrheological modifier is highly effective in diesel oil,distillate and mineral oil-based invert fluids.

Suitable For Base Oil : Diesel Oil, Mineral Oil , Synthetic oil

Performance : Suspension ,Protect The Well wall, Return Cuttings, Cool The Bit,Thickening And High Temperature Stability.

Advantage :

- Effectively suspends weighting materials and other solids

- Maintains suspension over a wide temperature range

- Eliminates need for chemical activators

- Organoclay is easy to disperse and rapid yielding

- Suspends weighting materials and other solids

Rheological Modifier Use For Paints , Coatings , Inks

Rheological modifier is an organically modified montmorillonite clay for solvent-based systems of low,medium and high polarity. Camp Shinning also produce water based inorganic rheological modifier.

Typical Applications:

Alkyd paint,Zinc-rich paint,Anti-corrosion paint,Bituminous paint,Chlorinated rubber paint,Marine paint,Primer paint,Road paint,Silica paint,None solvent epoxy paint etc.

Advantage :

1, High gelling efficiency over low, medium and high polarity organic liquids.

2, Exerts strong film reinforce action in organic binder systems.

3, High viscosity and excellent thickening property over a wide temperature range.

4, Imparts particle suspension, preventing hard settling of pigment and fillers.

5, Organoclay reproducible thixotropic consistency over a wide temperature range.

Rheological Modifier Use For Grease , Lubricant

Rheological modifier can be single dispersed in the base oil made bentonite grease, or can be used as a thickener and suspense agent in solid lubricants. As a thickening agent with good thickening properties,anti-corrosion properties and temperature resistance.

Typical Applications: Grease , Lubricant

Suitable For Base Oil : Naphthenic base oil , Paraffin base oil, Recovery oil (Diesel Oil, Mineral Oil , Synthetic oil)

Advantage :

Rheological modifier could increase viscosity, provide thixotropy, prevent pigment settling during storage, improve flowing and leveling, improve high temperature stability, lubricating property, film forming property, water resisting property and chemical stability

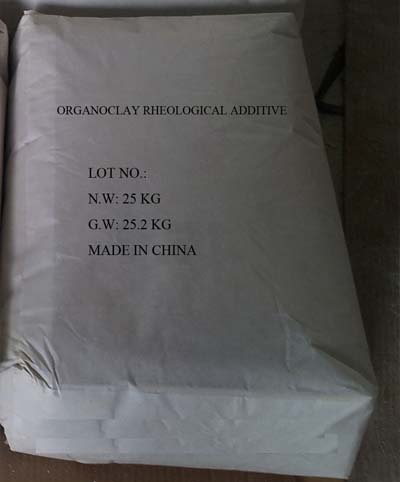

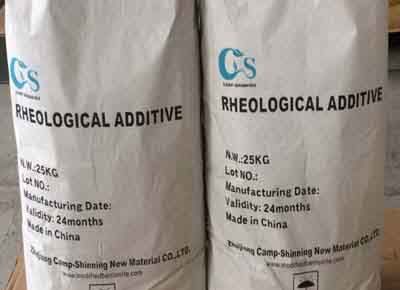

Packing: Kraft complex interior with PE.

The Weight: 25Kg/Bag, 22.68Kg/Bag(50lb) Or Customize.

Rheological Modifier Use For Inks

Rheological modifier is an ink thickener and uv ink additives,As raw materials used to make ink with good performance of anti settling and anti sagging.

Typical Applications: Offset Inks,Screen Printing Inks,News Ink,Lithographic Ink,Letterpress And Gravure Inks

Suitable For Base Oil : Diesel Oil, Mineral Oil , Synthetic oil

Advantage :

Rheological modifier could increase viscosity, provide thixotropy, prevent pigment settling during storage, improve flowing and leveling, improve high temperature stability, lubricating property, film forming property, water resisting property and chemical stability

Packing: Kraft complex interior with PE. 25Kg/Bag,22.68Kg/Bag(50lb) Or Customize.

Rheological modifier supplier, Camp Shinning is a group company, the branch company includes Zhejiang Camp Shinning New Material Co.Ltd, Hangzhou

Camp Shinning Co.Ltd, Zhejiang Camp Shinning Electricls Co.Ltd, Autofull Bentonite Co.Ltd

Camp Shinning has its own bentonite ore mine. We tend to offer you a one-stop solution for rheological modifiers for paints, coatings, inks, grease lubricants,

and oil drilling mud.

Camp Shinning can OEM a different kind of rheological modifier for you. Those rheological modifiers include rheological modifiers for oil drilling fluids, rheological modifiers for paint coatings, rheological modifiers for inks, rheological modifiers for grease, and more.

As an ISO 9001 certified rheological modifier manufacturer, Camp Shinning controls the manufacturing processes strictly. We can follow up with different standards such as SGS according to your demands.

Camp Shinning keeps the samples of each batch of rheological modifier, so that the samples can be traced and the quality can be inquired in case of subsequent quality problems so that the questions raised by each customer can be answered in the shortest time.

In one word, Camp Shinning is a one-stop solution OEM rheological modifier manufacturer. We can adjust our content of the rheology modifier to meet your request for your formulation. so you can focus on how to deliver value to your customers. Send us an inquiry now; we will respond with a perfect rheological modifier for you.

Camp Shinning Rheological Modifier

Advanced Equipment Test Rheological Modifier

In order to ensure the stable quality of each batch of organoclay rheological modifiers, Camp Shinning has purchased a lot of advanced testing equipment.

Especially the testing equipment for rheological modifier used in the oil field. Camp Shinning has almost led the production market in China.

This is why Camp Shinning can maintain the stability of the quality of each batch organoclay rheological modifier and protect the distributor’s advantage of good price in the market.

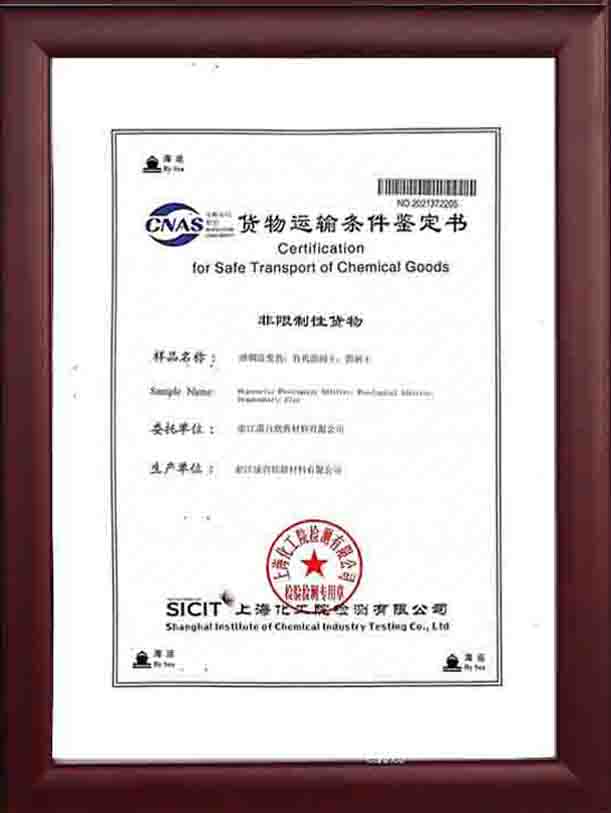

Rheological Modifier Certification

IIn order to take advantage of being a rheological modifier supplier and manufacturer in the market. In the past few years, Camp Shinning has won many certificates. ISO Certification, Audited Supplier, Certification For Safe Transport Of Chemical Goods,

Auditor Supplier

The certified supplier issued by the website of Made-in-China.com is the best recognition of Camp Shinning. It represents that Camp Shinning is a trustworthy Chinese organoclay supplier and manufacturer.

Certification For Safe Transport Of Chemical Goods

Camp Shinning has Certification For Safe Transport Of Chemical Goods. This means that the organoclay produced by Camp Shinning is allowed to be freely transported by sea and air, and is a non-hazardous product.

ISO Certification

The ISO certificate means that the organoclay produced by Camp Shinning is strictly regulated and produced in accordance with ISO standards.

Patent

The strong R&D capabilities enable Camp Shinning to have its own technology patents, which is also the best proof of Camp Shinning's market competitiveness.We will continue to research and develop more market-efficient organoclay with good price.

Camp Shinning Rheological Modifier

Rheological Modifier Supplier & Manufacturer

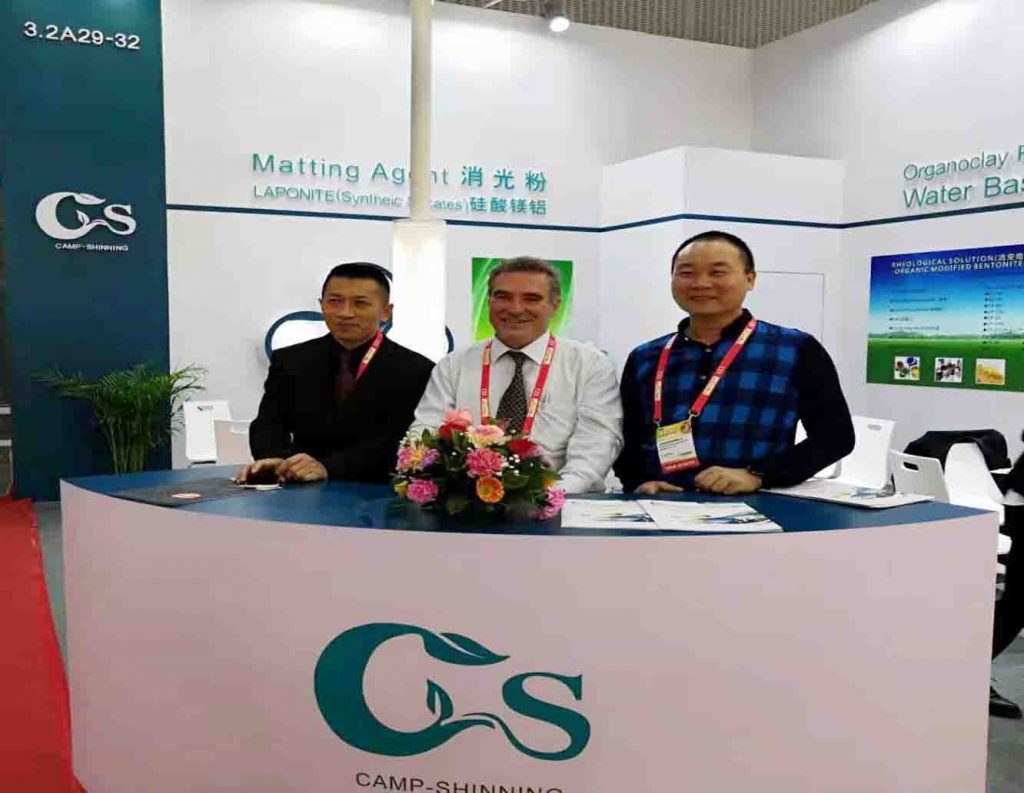

Rheological Modifier Exhibition

The exhibition is the best channel for buyers to understand the professionalism of Chinese suppliers and manufacturers. Every year, Camp Shinning recommends the best-selling rheological modifier and new products to professional buyers, so that buyers can clearly understand the professionalism of our production and the unique price in the exhibition.

The exhibitions we participate in includes OTC USA,Global Petroleum Show and China Coat Show etc.

Inquire Us Now

Rheological Modifier FAQ Guide Outline

It’s not easy to find a reliable rheological modifier manufacturer & supplier with a reasonable price; Camp Shinning is the right one for you.

Rheological modifiers are popularly used in different kinds of applications. They are intended to improve thixotropy, dispersibility, rheology, and suspension etc

From application aspects, rheological modifier can be categorized into oil drilling mud, grease lubricant, inks and paints coatings etc.

You may ask why I should choose a rheological modifier for my formulations. This is because rheological modifier has a very high anti sagging and anti settling to protect your producrs .

You could also choose the rheological modifier if you require even higher suspension in oil drilling mud. Camp Shinning can adjust the content of bentonite according to your formulations.

Camp Shinning, one of the professional rheological modifier manufacturers, is always here to support you to make your high-quality organic bentonite clay . We will offer you a long term and one-stop solution according to your application requirements.

What Is Rheological Modifier ?

Rheological modifier is an organically processed bentonite powder,it is a naturally occurring clay mineral. Rheological modifier is also called organophilic bentonite clay and rheology modifier.It is a coating additive,grease additive and drilling additives.

Five Major Application And Functions Of Organoclay Bentonite rheological modifier

| Applications | Advantage |

| Oil Drilling Mud | Effectively suspends weighting materials and other solids |

| Paints,Coatings | Easy dispersing,good thixotropy |

| Inks | Sag resistance without impairing flow and leveling, preventing hard settling |

| Grease Lubricant | The gel is colourless and of high clarity |

Different grades of rheological modifier have different activation requirements

Rheological modifier is a ORGANOCLAY for paints and inks in low, medium and high polar solvent systems such as aliphatic hydrocarbons, esters, and ketones.

Rheological modifier can be self-activated and dispersed in xylene, xylene-esters (such as butyl acetate), xylene-ketones (such as cyclohexanone) and other medium and high polar solvent systems.

In 200# solvent oil, white oil (mineral alcohol) and other aliphatic hydrocarbon low-polarity solvent systems, an activator should be added to aid dispersion (the activator is 95% ethanol, which is 40-60% of the organic earth weight). It is highly polar in alcohols. In the system (such as butanol), an activator, such as propylene carbonate, needs to be added.

What Is The Application Of Rheological modifier ?

★Application in oil drilling

Rheological modifier is the most basic lipophilic colloid in oil-based drilling fluids, and it is an indispensable additive. In the oil-based drilling fluid, it can not only increase the viscosity and shear force of the drilling fluid, but also reduce the filtration loss of the oil-based drilling fluid.

★Application in grease

Rheological modifier bentonite grease is a gelatinized grease made from organic soil and is a thickener. It has the advantages of high use temperature, no fear of moisture, no fear of humidity, colloidal stability, good chemical and thermal stability, and excellent extreme pressure resistance.

★Application in paint

Rheological modifier is widely used in coatings. The use of organic bentonite in paint and ink can improve its thixotropy, suspension emulsion and stability, improve spreadability, prevent sagging, sagging, increase paint film thickness, prevent paint precipitation, improve storage stability, and improve paint quality and paint Quality and service life of parts.

★Application in cosmetics

Incorporate rheological modifier into various cosmetics, such as cream, grease, toothpaste and nail polish. Rheological modifier is used to improve thixotropy and play a role. China supplier of organoclay would like to recommend you stable quality products.

What are the characteristics of Rheological modifier ?

Rheological modifier has good adsorption, suspension, water absorption, lubricity, cohesiveness, colloid dispersion, adhesion and good cation exchange properties after encountering water. Because of its many special characteristics, bentonite is widely used in hundreds of industries and is called “organoclay rheological modifier ” by people.

What cClor is the Appearance of Rheological Modifier ?

The appearance of rheological modifier is white. Compared with other colors of bentonite, white bentonite has low iron content, less impurities, and high purity, so the application value of white bentonite is also relatively high. Broadly speaking, it is normal for the bentonite to show a variety of different colors. This is due to the difference in the ore belt area and the different depth of the original ore of the bentonite. Due to the high iron content of bentonite ore, it is usually reddish and yellowish. In fact, for companies that do not require high color, the performance of bentonite is not affected by the color.

Good quality bentonite rheological modifier has the following remarkable characteristics:

(1) Less impurities and high purity:

High-quality rheological modifier bentonite is characterized by low impurities, high purity, and oily luster. It has a smooth feel to the touch with our hands and is jelly-like.

Under normal circumstances, most of the bentonite we buy is processed powder, and the common specifications for fineness are 200 mesh or 325 mesh. The appearance of a good-quality bentonite product is pure white powder that we can observe with the naked eye.

(2) Rapid expansion in contact with water:

Another notable feature of high-quality bentonite is that it absorbs water quickly. After being fully dissolved in water, it can swell to at least 10-25 times its own volume, so it can become a colloidal solution.

(3) Strong cation exchange and strong adsorption:

Bentonite has strong cation exchange capacity and adsorption capacity, so bentonite can absorb or absorb various odors and colors. It is mixed with grease to make the grease smoother.

(4) Good suspension, not easy to settle:

Putting the purified bentonite powder in water has very good dispersibility and is not easy to settle.

The role of organic bentonite in oil-based mud:

(1) Protect the shaft wall: it can be penetrated, bonded and reinforced in the sand and gravel gaps around the shaft wall, so as to protect the shaft wall from collapsing.

(2) Cooling the drill tool: Rheological modifier can effectively reduce the high temperature generated when the drill bit is cutting with the ground, and cool the drill tool to prevent burning.

(3)Leakage plugging: Organic bentonite and water can form a thin and impermeable mud wall to prevent water leakage accidents and play a role of plugging.

(4) Clean the bottom of the well: The organic bentonite mud can carry the cuttings and debris at the bottom of the well along with the rotation of the drill pipe to keep the bottom of the well clean.

(5) Improve mud performance: The high-adhesive gel solution formed after the bentonite and water slurry can effectively increase the plastic viscosity, dynamic shear force, and static shear force of the mud system, thereby increasing the suspension and suspension of drill cuttings by the drilling fluid. Carrying ability.

(6) Low filter vector: Organic bentonite can be equipped with high-performance drilling fluid, which not only has less water loss but also has strong wall protection performance.

(7) Lubrication and decompression: Organic bentonite can effectively lubricate drilling tools and drill pipes, prevent borehole expansion and reduce drilling pressure.

(8) Balance formation pressure: Bentonite can stabilize and balance formation pressure for well-walled bentonite.

(9) Improve drilling rate: The efficiency of drilling engineering using bentonite is significantly increased by more than 30%, effectively reducing drilling construction costs.

What is the amount of rheological modifier added in the putty powder?

(1) Putty powder: Generally, the amount of putty powder and bentonite recommended by our bentonite manufacturers is controlled by adding 8-15 kg of bentonite per ton of putty powder to achieve a good water retention and lubricating effect.

(2) Putty paste: Putty paste can control the amount of bentonite added to 10~20 kg per ton of putty paste for the best effect.

Is Camp Shining a credible rheological modifier supplier?

Camp Shining is a leading rheological modifier manufacturer & supplier in China with over 20 years of experience. Our great experience in the bentonite industry enables us to manufacture high quality organoclay.

On top of that, Camp Shining is a certified Rheological modifier manufacturer. Camp Shining has ISO 19001 quality system certifications.

We have our bentonite mine which gives us high grade organoclay. We have a modern manufacturing factory with best in class equipment.

With these, we can manufacture and supply you with quality organoclay on time. This makes Camp Shining a credible and reliable organoclay manufacturer.

The role of bentonite organoclay in coatings and paints

(1) Organoclay Bentonite in the coating can enhance the water resistance of the coating and improve the viscosity, strength and adhesion of the coating.

(2) Effectively improve the anti-settling ability and suspension performance of the coating.

(3) It can play the role of water retention, slow drying and lubrication in the coating, thereby improving the painting performance of the coating construction.

(4) It can be used as a dispersant for coatings, effectively solving the phenomenon of poor dispersion of coatings and improving the quality of coating products.

(6) A small amount of bentonite rheological additive can be added to enhance the hiding power of the coating.

(7) Organoclay Bentonite has cold resistance and high temperature resistance, and the prepared coating can still be used at high and low temperatures in summer and winter.

(8) The hydration solution of bentonite has the advantages of good strength, good stability, good adhesion, and high adhesion. Adding to the coating can solve the defects of low strength and poor adhesion of the finished coating and can form a uniform thickness, smooth coating.

(9) Since bentonite can greatly enhance the anti-settling ability of the coating, at this time we can add a part of heavy calcium carbonate powder to replace the light calcium carbonate powder, so as to reduce the production cost of the coating and improve the economic benefits of the enterprise.

(10) Most of the materials used in the production of polyvinyl alcohol series coatings are light calcium carbonate, which is relatively expensive. We can add part of bentonite to replace some light calcium carbonate components, and reduce the amount of light calcium carbonate used in coating products to achieve the purpose of reducing costs

(11) Bentonite has good gelling and dispersibility after being fully diluted with a large amount of water. It can release charged ions in water, and the electrical repulsion between these ions can act as a dispersant in the coating.

(12) In waterproof coatings, high-speed moving bentonite colloidal particles collide with hot asphalt, chop it, and then crush and gel the asphalt. Polar substances in gelled asphalt particles

The bentonite particles are easily absorbed by the bentonite particles, thereby forming a colloidal hydration film on the surface of the asphalt particles, reducing the interfacial tension between the asphalt and water, preventing the asphalt particles from re-aggregating, and forming a stable dispersed phase, thereby allowing the bentonite to play a role in the coating.

(13) The purpose of adding bentonite to paint:

The bentonite used in the paint is organically modified to improve its compatibility with the resin system in the paint and coating.

(14) Organophilic Bentonite can greatly improve the suspension, adhesion, brushability and water resistance of coatings.

(15) Among the putty powder, Organoclay bentonite has good water swelling and lubricating properties. It has the effect of water retention, slow drying and lubrication when the putty plaster is used to plaster the wall, and the paint master has a good slippery effect during construction. It feels like your putty product Especially easy to use.

What are the benefits of using organoclay bentonite for putty powder?

We know that organic bentonite is a kind of non-metallic mineral clay with montmorillonite as the main component. The difference between this kind of clay and ordinary clay is that it has a special water-absorbing swelling effect and can absorb 8-10 times its own volume of water, and It expands rapidly to 20~30 times, and has a good thixotropic lubrication effect. Therefore, when we add bentonite to putty powder or putty paste, it has many advantages, such as good thickening, thickening, water retention and lubrication effects.

Through the use of organic clay, practice has proved that the use of putty powder and bentonite has the following benefits:

(1) Water retention: In summer, when the putty powder for interior walls dries too fast, or when the scraping and sticking force is too low, we can add part of the bentonite to effectively increase the viscosity, water retention and lubrication, and it will not be used when scraping the putty. Laborious and flexible, making construction much easier!

(2) Prevent dehydration: The finished product of putty paste will inevitably appear dehydration after storage time is too long. Adding some organic bentonite can effectively solve this phenomenon and effectively delay the storage time of putty paste.

What is the dosage of organoclay bentonite added in the coatings and paints?

Addition levels are typically in 0.2%~2.0%. Polar activator (95% Ethanol or 95% Methanol) is needed. Normally addition level of polar activator is recommended to be 30%~40% of organoclay in weight.

What is the price of rheological modifier ?

The price of rheological modifier according to different application, different ingredients and formulas, when Camp Shinning produces rheological modifier, the cost is very different.

Here, we provide an approximate range for purchasers’ reference.

Usually, our price is between US$1500 per ton to USD2700 per ton.

If you can clearly tell us your application and the grade of bentonite organoclay you have used in the past, we will recommend a model with similar performance. Because we have our own bentonite mine and years of production experience, we can effectively control costs and ensure our price advantage.

This is the advantage of being a rheological modifier manufacturer and supplier.

What does the rheological modifier HS Code?

The HS code of Camp Shining’s rheological modifier is HS 2508.0000.

What is an rheological modifier CAS number?

The CAS number for Camp Shining’s rheological modifier is CAS 68953 – 58 -2

What is the package Of rheological modifier?

Kraft paper bag with PE liner or multi-wall paper sacks or customized. 25kg/bag or 22.68kg/bag or customized

What Is The Requestment For Storage?

Organoclay should store in a dry, well-ventilated area with temperature of 0℃-30℃. Keep container closed. The quality guarantee period is 24 months.

What is the delivery time for Camp Shining Organoclay?

The delivery time for Camp Shining Organoclay is 7-10 working days after receiving your deposit.

Intruduction Of Organoclay

Organoclay, also named organic bentonite clay, organic thickener and rheology modifier,is a fine chemical product developed in recent years.It is a white or grayish white powder which is non-poisinous.

Organoclay is a kind of inorganic mineral and organic ammonium complex. Organic bentonite clay is composed by inserting an organic covering agent through ion exchange technology.

The raw material of organolay is Bentonite which has the characteristics of strong adsorption and swelling characteristics, good dispersion in water and good thixotropy in solution.

The reason why bentonite has such characteristics is that,there are many clay minerals such as montmorillonite

in bentonite.Montmorillonite has high hydration energy.It is a kind of aluminosilicate mineral with unique properties.

When the temperature reaches 100 ~ 200 ℃, organoclay montmorillonite will lose water gradually. After dehydration, montmorillonite can reabsorb water molecules or other polar molecules. When they absorb water, they can also expand and exceed the original volume by several times.

Swelling, high dispersion and thixotropy in organic media are the main characteristics of organoclay bentonite . And it’s easily soluble in hydrocarbon solvents; it has high physical and chemical properties, and its ability to disperse, expand are better than those of the same kind of sodium bentonite and lose water are lower. Besides,it has certain wet state and dry state cohesiveness,making it has a wide range of applications.

Application purpose

Organoclay bentonite are widely used in paint, ink, grease, oilfield drilling and other industries. But it can not be used for oil-water filtration.This is due to the poor adsorption capacity of natural bentonite for hydrophobic organic matter, which did not change when natural bentonite was transformed into organic bentonite clay.

Organoclay bentonite can form gelatin in various organic solvents, Oils and liquid resins.Organoclay rheological additive has good thickening, thixotropy, suspension stability, high temperature stability, lubricity, film-forming property, water resistance and chemical stability.

Organoclay rheological additive has important application value in the coating industry. Generally used as anti settling agent and thickening agent, it is used as anti corrosion coating, which has the characteristics of corrosion resistance, wear resistance, salt water erosion resistance, impact resistance and not easy to wet.

In high-speed printing ink, according to the need to adjust the ink consistency, viscosity and control permeability.

In high temperature grease lubricant, Organoclay rheological additive are especially used to prepare high temperature grease suitable for high temperature and long time continuous operation.

In oil drilling field , organoclay bentonite is the most basic lipophilic colloid and an indispensable additive. It can not only improve the viscosity and shear force of drilling fluid, but also reduce the filtration loss of oil based drilling fluid. Generally used as latex stabilizer.

Organoclay bentonites used for glass fiber resin can improve thixotropy and suspension of the resin, so as to improve the storage stability of the resin, prevent the separation of glass and resin in the curing process, promote pumping, spraying and prevent sagging.

In addition, Camp Shinning produce organoclays are also widely used in pesticides, plastics, electronics and other industries.

Market situation and Prospect

At present, the price of organoclay bentonites is about USD1000.00 per ton at a low price and USD2600.00 to USD2700.00 per ton at a high price. China’s domestic demand for grease has reached 400000 tons per year.

With the continuous progress of organic bentonite clay production and processing technology and interest driven, more bentonite enterprises began to produce organic bentonite.

It is predicted that the demand for organobentonites in paint and coating industry alone will be very higher quantity per year; the demand for organoclay bentonites in the grease industry, especially solvent based organoclay bentonite , will reach about more higher quantity ; the demand for organoclay bentonites in oil drilling and shale oil (gas) drilling will reach about 12000-20000 tons per year.

In the next few years, the domestic market demand for organoclay bentonites will reach 300000-400000 tons per year, and organic bentonite clay will continue to develop in the direction of refinement, serialization and functionalization.

The main development direction of organobentonite industry is to actively carry out the research of organoclay bentonite production technology, speed up the industrialization transformation of achievements, expand the application field of organoclay rheological additive bentonite, and realize the comprehensive utilization of organobentonite with high efficiency and high added value.

At last, it should be noted that the raw material for the preparation of organoclay bentonites must be raw bentonite,while the quality of bentonite, the structure, dosage, usage and preparation conditions of organic covering agent are the main factors affecting the quality of organic bentonite clay.

Conclusion

If this is your first time to purchase rheological modifier , understanding organic bentonite clay can be cumbersome.

This is why I wrote this guide for you.

I want to help you avoid problems, quality, price or delivery time that comes with rheological modifier supplier and manufacturer.

I just want to make this process easy and simple for you to understand.

But again, you don’t have to worry about

rheological modifiers – Camp Shinning is here to help you.

Just tell us what your applications, or what grade of

rheological modifier do you used before and to which market…

We’ll provide an organoclay solution for your specific needs.

If you have any other questions, you are welcome to email us or contact us by whatsapp, and we will respond in a timely manner within 24 hours.

Our Sales Dept :

Cell(Whatsapp):+86-13185071071

Rheology modifiers for oil is a wide range of field.It also includes rheology modifiers in cosmetics,rheology modifiers in paints and rheology modifiers for waterborne paints.When rheologieadditive use in drilling mud rheology,rheology of drilling mud is very idealized additive.

Email: [email protected] Wechat/Whatsapp: +86-13185071071