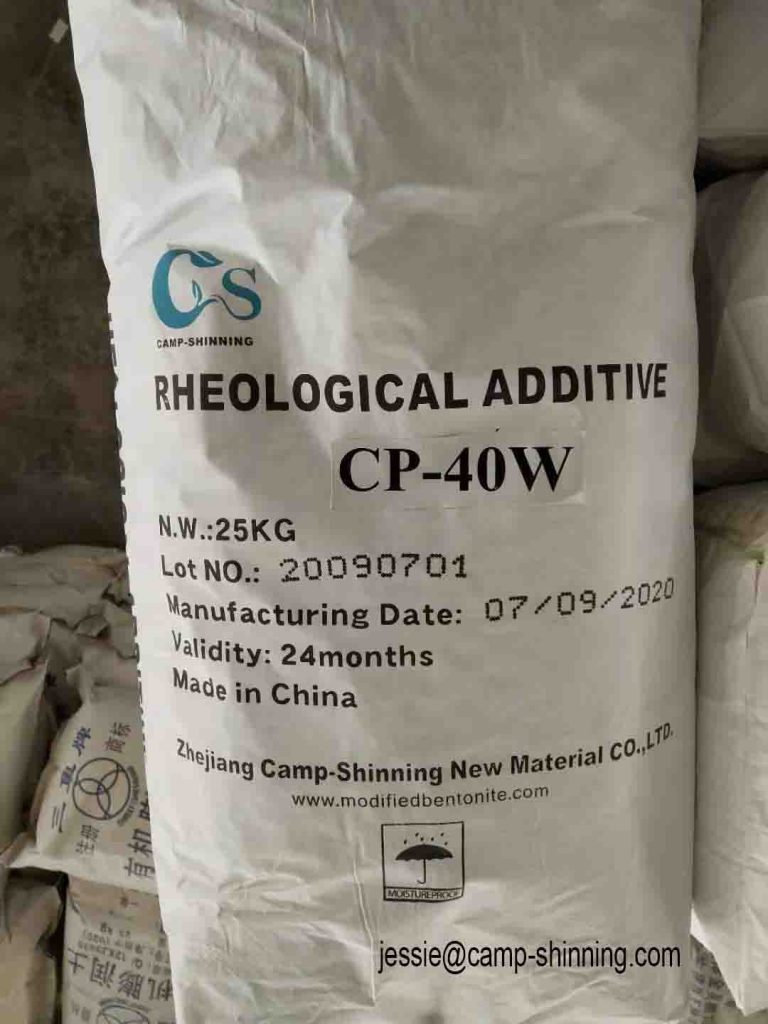

Pure calcium bentonite clay

Product Name : Pure calcium bentonite clay

Color : Off – White Organoclay Powder

Application: Thixotropic Uses Paints | Coatings | Grease | Oil drilling Mud

Materials : Alkyl Quaternary Ammonium bentonite

Certificate: ISO 9001

Packing: 25Kg/Bag,22.68 (50lb)/Bag Or Customize

16MT/20FCL With Pallet, 22MT/40FCL With Pallet.

Features : Thixotropy, Thickening, Anti-Settling, Anti-Sagging,

Sample Service : Pure calcium bentonite clay Sample Available.

Brand : Camp – Shinning Organoclay

Pure calcium bentonite clay

Pure calcium bentonite clay,natural calcium bentonite clay is provided by Camp Shinning,it is used for drilling industry.

Pure calcium bentonite clay CP-DRI is used in vertical drilling fluids to increase viscosity and filtration control. CP-DRI types of bentonite clay is also ideal in drilling fluids because it expands when exposed to water. This expansion helps down hole formations to be sealed from invading drilling fluids. The Drilling bentonite extracts the drill cuttings from around the drill bit, which are then floated to the surface. Bentonite also serves to cool and lubricate the drill bit as well as seals the drill hole against seepage and to prevent wall cave-ins.Natural calcium bentonite clay is mainly use in fresh pure water rotary drilling conditions as water quality will affect bentonite performance.

Sale Dept: [email protected]

Cell(Whatsapp): +86-13185071071

Advantages:

Good suspension

High thixotropy

Little filtrated volume

Excellent capacity of making mud

Easy to adjust the density of the well drilling slurry

Typical properties:

Suspension Properties | Specification |

Appearance | Off-white powder |

Viscometer dial reading at 600r/min | Min.30 |

Plastic viscosity Ratio | Max.3 |

Filtrate volume | Max.15 ml |

Residue of diameter greater than 200mesh | Max mass fraction 5.0% |

Bentonite application

Types of bentonite clay CP-DRI is suitable for all type of freshwater mud rotary drilling.

CP-DRI can also be used as a seal for earthen structures, slurry trenching, tunnel boring and foundation drill.

Mixing and dosage:

Mixing ratios are based on the use of freshwater; water purity will affect bentonite performance. For best results, acidic and hard make-up water should be pretreated with SODA ASH to a pH of 8.5-9.5. Add PREMIUM GEL slowly through jet/hopper mixer.The quantity of bentonite used is variable depending upon the depth of the hole to be drilled. Generally one tonne of bentonite is used to prepare about 100 barrels of mud.

Packing:

25kg/bag; or 50kg/bag, packed by 800kg or 1000kg super sacks.

How To Use Thixotropic clay

- Pre-gel method

- Polar activator is not necessary:

- Main solvent xylene: 95~92%

- Thixotropic clay :5~8%

- Dispersing 5-15min, gel is finished.

- Polar activator is necessary:

- In aromatic solvent, the recommend activator is methyl acohol/water (95%/5%)/ acolhol/water (95%/5%), the dosage is 33%-45% based on the weight of CP-720B.

- In mineral oil (such as 200#), white oil, diesel oil, the recommend activator is methyl acohol/water (95%/5%)/acolhol/water(95%/5%), the dosage is 33%-60% based on the weight of CP-720B.

- Procedure of adding gel:

- Charge solvent and resin to mill

- Slowly add the gel

- Dispersing 5-10min

- Wetting agent (if required)

- Disperse completely to desired fineness

- Dilute to desired viscosity

- Add directly with powder

- Charge solvent and resin

- Add Thixotropic clay slowly

- Disperse 10-15min

D .Add polar activator (if necessary)

- Disperse 10-15min at high speed

- Add wetting agent and other additive

- G.Grind and next procedure

It can be added directly in powder under high shear condition. The addition is recommended to be before grinding procedure to get the best effectiveness. Addition level is commonly 0.1%~2.0%. If add polar activator and make pre-gel, better efficiency can be achieved.

oilfield specialty chemicals

Pure calcium bentonite clay