Hydroxypropylmethyl Cellulose

Hydroxypropylmethyl Cellulose | HPMC is a product with a wide range of applications, which is typically used as a tile adhesive,The use of ha PMC in ceramic tile pointing agents, self leveling cement mortar, and some insulation mortars, especially in polymer mortars with high flexibility requirements, is very effective.

Hydroxypropyl methylcellulose HPMC is widely used in bonding mortar, grinding mortar, and decorative mortar for some exterior wall insulation systems. HPMC is also widely used in interior and exterior wall putty and flexible crack-resistant mortar.

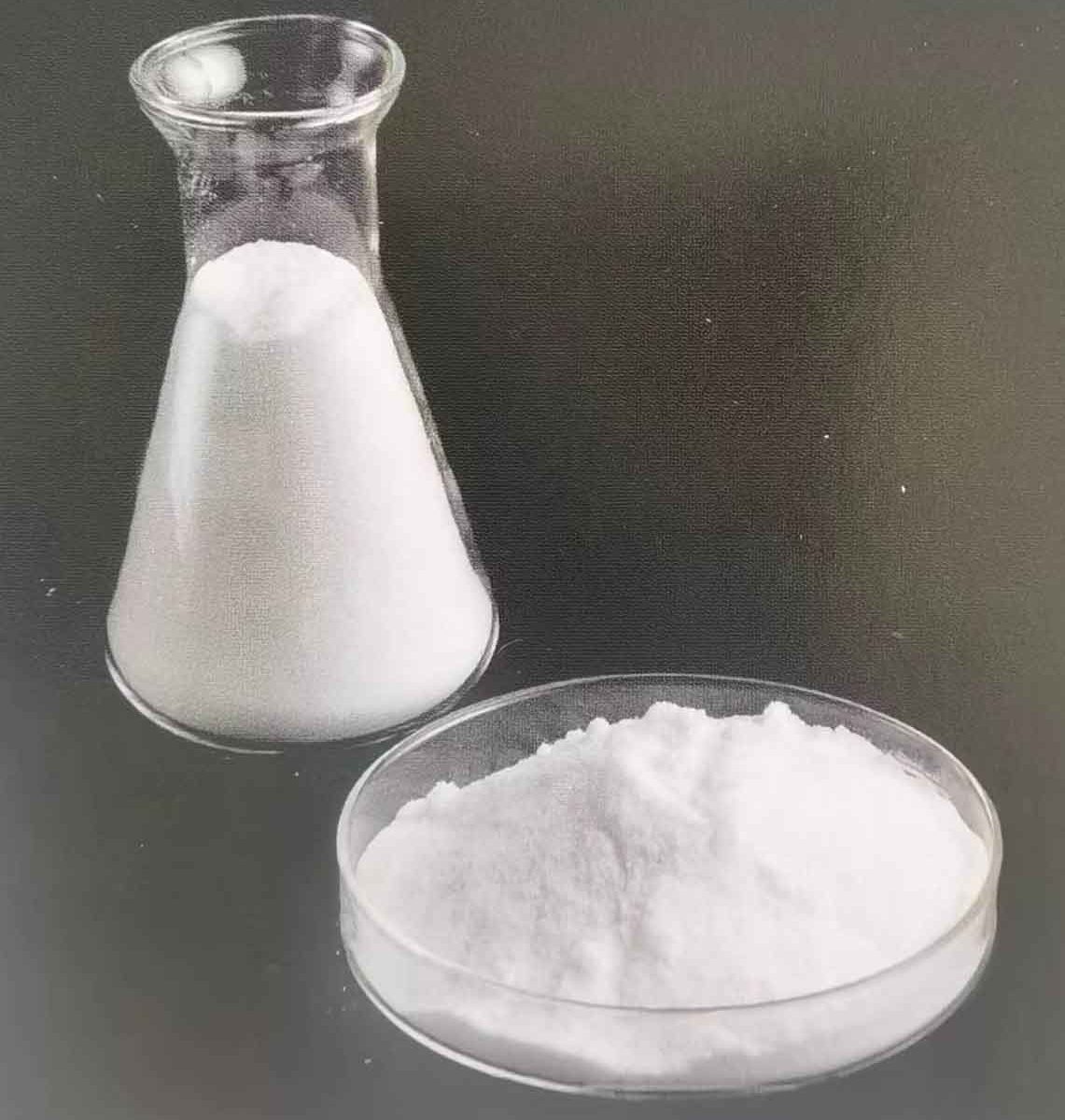

This material is a non-ionic cellulose rice made from natural polymer material cellulose through a series of reactions. hydroxypropyl methylcellulose is a odorless, odorless, non-toxic organic compound that grows into a clear or slightly cloudy colloidal solution in cold water.

Hydroxypropyl methylcellulose greatest advantage is that hydroxypropyl methyl cellulose has water retention, thickening, combination and dispersion, excellent emulsifying ability, film forming and suspension performance, and is also excellent in gel and western areas. It is an oil paint additive with outstanding surface activity and protective colloid characteristics.

In addition to the application fields mentioned above,hydroxypropyl methylcellulose is also widely used in fields such as coatings, industry, medicine, food, daily chemicals, ceramics, synthetic resins, etc.

hydroxypropyl methylcellulose is a granular and powdery solid powder with a white or yellow fibrous appearance.Its dry weight loss moisture content is greater than or equal to 5%.

Usually, hydroxypropyl methylcellulose hpmc pH range is between 4.0 and 8.0, and its mesh count is 98% through 100 mesh.The viscosity also ranges from 100 to 200000, in 2% of the solution.

What is hydroxypropyl methylcellulose ?

1), Hydroxypropylmethyl Cellulose is applied to interior and exterior wall putty.

Good water retention is its biggest advantage, as hydroxypropyl methylcellulose hpmc preserves the moisture in the mortar, allowing complete solidification of cement, lime, and calcium, while also ensuring that workers can achieve multiple batches of putty scraping for workers during operation.

Good application properties, easy application due to fiber technology providing suitable viscosity and good plasticity. hydroxypropyl methylcellulose hpmc does not stick to the knife, which improves the construction efficiency, which is especially remarkable.

What is hydroxypropyl methylcellulose?

2) Hydroxypropylmethyl Cellulose is applied to ceramic tile adhesive.

hydroxypropyl methylcellulose hpmc is used as a thickener in paint coatings and adhesive, just like organoclay bentonite.

In this process of use, water retention is still its biggest advantage.

hydroxypropyl methyl cellulose can reduce the absorption of water during the process of mortar, substrate, and ceramic tile lunch boxes, and retain the water as much as possible in the adhesive, allowing the cement to completely solidify, significantly improving the ceramic tile adhesive’s ability to penetrate the underworld and preventing the hardness of the tiles from hollowing out or falling off.

This greatly improves work efficiency during construction.

hydroxypropyl methylcellulose HPMC can improve bonding strength and improve anti – slip mobility, as hydroxypropyl methyl cellulose ensures that tiles do not slide during construction and have a strong bond after construction.

3),Hydroxypropyl methylcellulose is used for gypsum based plastering.

The outstanding water retention properties enable hydroxypropylmethyl cellulose to retain the moisture in the mortar well, allowing the gypsum to completely solidify, The higher the viscosity of the solution, the stronger its water retention capacity, while conversely, its water retention capacity will decrease significantly.

Excellent construction performance.hydroxypropylmethyl cellulose provides suitable viscosity and is easy to apply. Watermelons are particularly smooth and non stick knife, improving construction efficiency.

The above is what we mentioned. hydroxypropyl methyl cellulose has good formula stability, outstanding water retention, and is easy to construct.Our product has the advantages of low viscosity construction and high viscosity water retention, so its water retention is our biggest advantage and feature.

Fortunately, the main performance of the construction is that hydroxypropylmethyl cellulose is easy for watermelons to be smooth, with good filling properties and a uniform feel.

hydroxypropylmethyl cellulose has strong compatibility and can be used in many different types of putty and gypsum products.

Our starting point is to maintain the stability and high purity of the formula while ensuring water retention and workability.